Project Overview

By 2030, renewable Energy Sources (RES), and its infrastructures, are expected to increase 40% in Europe. Parts of RES strategies are onshore and offshore wind energy. The investment into new RES infrastructure implies an update of the current wind turbines, resulting in waste of the composite materials that constitute blades. To turn RES into the most promising and economically viable sources of renewable energy, we need to provide clean renewable energy without any emissions during operation. The blades, among the most important components in the wind turbines, made with composite, are currently regarded as unrecyclable. It is estimated that by 2050 the end-of-life (EOL) blades waste will generate more than 2 Mt annually, and cumulative blade waste in 2050 will lie between 21.4 Mt and 69.4 Mt, worldwide. EOL options for decommissioning wind turbine blades should be explored with the aim of providing environmentally favorable guidelines for managing wind turbine blade waste, and the possibility for material recovery and recycling is crucial if circular economy is the goal in the wind power sector.

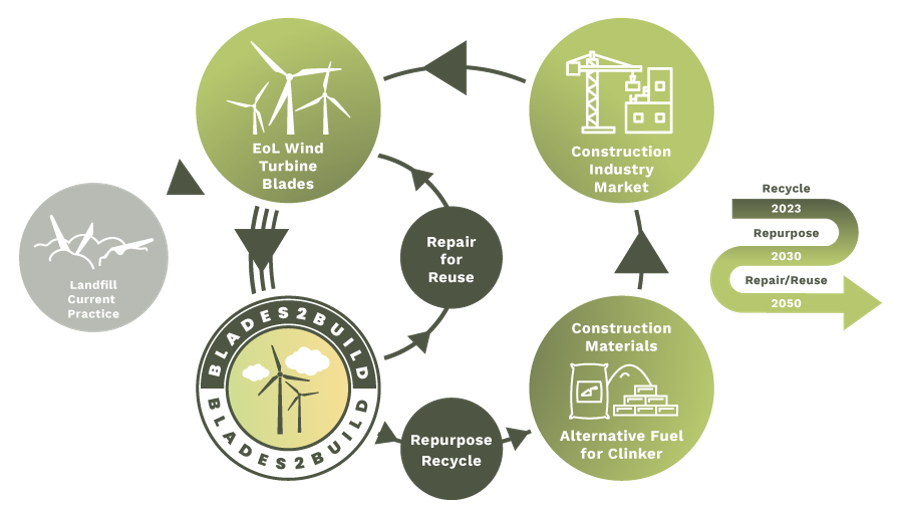

One possibility to avoid the accumulation of EOL blades in the environment is to convert the composite blades into new environmentally friendly building materials. This option would demand some processing of the composite waste. Another option could be the reuse of the blades directly without much processing, e.g., as new blades or as other products. Furthermore, the composite waste from blades could be combined with similar waste from other industrial sectors to enlarge the potential of a composite wind blade recycling process.

Therefore, the general scope of the proposed project is to evaluate and demonstrate in large scale the possibility of recycling or resource recovery from blades and similar waste materials in a large consortium with some of Europe’s key players in areas of importance for the project.

The aim of BLADES2BUILD is to improve and support circularity options of end-of-life wind blades by exploring three different circular stages:

The Concept:

Objectives:

The BLADES2BUILD consortium combines world-leading industrial partners with cutting-edge European universities to create an innovative solution for End-Of-Life Wind Turbine Blades.

Project Partners:

Project Metrics:

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Climate, Infrastructure and Environment Executive Agency (CINEA). Neither the European Union nor CINEA can be held responsible for them.